Optional remote on/off, Elec sch:hpr260xd pwr sply w/auto – Инструкция по эксплуатации Hypertherm HPR260XD Auto Gas

Страница 264

1

2

4

3

5

7

6

5

1

3

2

4

7

6

4

3

2

1

1

A

4

3

2

A

B

C

D

B

C

D

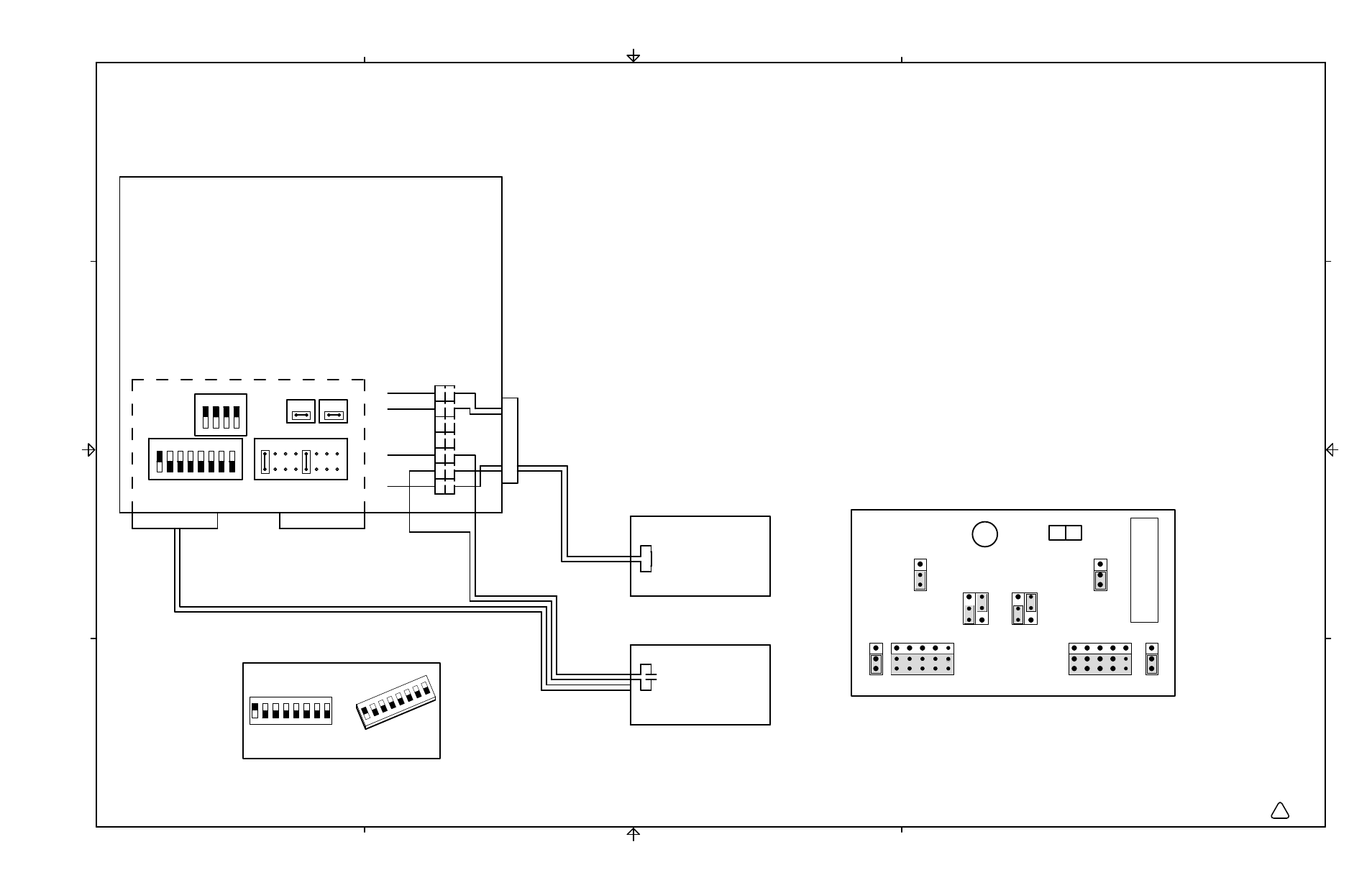

Interface

CNC

(Customer Supplied)

041993 CONTROL BOARD

S100

1 2

J303

3 4

3

2

1

4

J300A

J300B

Serial ID

Dipswitch

Jumper Block

Machine Motion

CNC Interface Cable

7

RED/BLK

RED

WHT

RED

Gas Console

078170

Gas Power Cable

Customer Supplied

Remote On/Off

J106

2

1

2

1

J107

Optional Remote On/Off

TB2

WHT

RED

RED/BLK

RED

6

2

1

1X1

Switches 2-8 are in the Off position

Switch 1 is in the On position

BMD

J2

BTR

J7

RS-232

J9

RS-422

BHST

AHST

J3

AMD

J5

J6

RS-422

J10

RS-232

ATR

J8

J1

SV

RIBBO

N

C

A

BL

E

Serial isolation board in a Hypertherm Automation controller

1 2 3 4 5 6 7 8

ON

1 2 3 4

S101

ON

Notes:

1) For single system installation set Serial ID (S100), Machine

Motion (J303), J106 & J107 as shown.

Relocate the white wire on TB2 from position #3 to position

#2. Connect customer supplied Remote On/Off cable in series

with the power supply and the gas console power switch.

Connect one terminal of the Remote On/Off cable to position

#2 on TB2 and the other terminal to position #3.

Refer to page 3 of the wiring diagram

Depress the Gas Console Power switch to the closed position (on position).

2) For a multi-system installation set up as described above, set jumpers as shown on the

multi-system interface page

3) The CNC will need a dedicated I/O for each system using the Remote On/Off feature

(contact should be rated for min. 24Vac, 0.5 Amp)

HPR PAC

Dry Cutting System

S100

3

1 2

6

5

4

8

7

Dipswitch setting example:

1 2 3 4 5 6 7 8

ON

* If a Hypertherm Automation controller is being used, and there are intermittent communication

failures (PS Link Failure), try removing the jumnpers on J104 and J105 on the control board, and the

termination jumper (J6 or J8) on the serial isolation board in the controler. Only remove

the termination jumper on the serial isolation board that is connected to the HPR

power supply. See figure below for details.

ON

ELEC SCH:HPR260XD PWR SPLY W/AUTO

B

013378

SHEET 20 OF 22

7-24