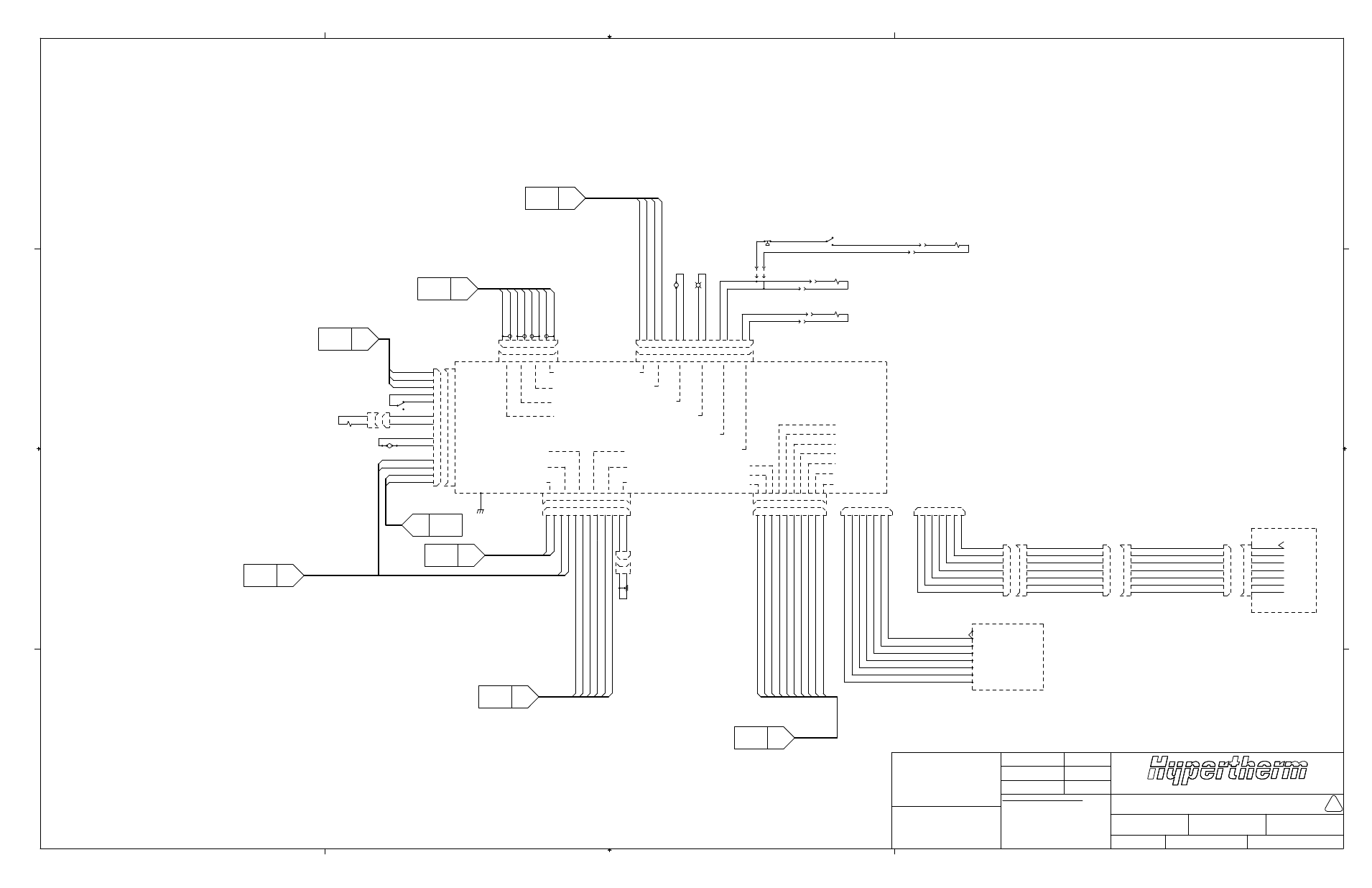

Elec/gas schem: max200 – Инструкция по эксплуатации Hypertherm MAX200 Hand Torch Plasma Arc Cutting System

Страница 160

V9

S1

71 RED/BLK

70 RED

69 RED/BLK

68 RED

R

E

D

68

PS4 181 RED/BLK

69 RED/BLK

V1

TEST

V3

RUN

182 RED

ON Light

DC Power

Interlocked

START

Plasma

Control PCB

Contactor

24 VAC

Main

3

2

1

72

12

3

73

4

6

5

12

2

67

66

R

E

D

W

H

T

R

E

D

R

E

D

/B

LK

W

H

T

R

E

D

CON1

Step Gas

13

8

REC1

7

65

64

PL5

14

16

15

R

E

D

/B

LK

R

E

D

LT2

Workpiece

Shield Gas

Valve

Switch

Test/Run

Gas

Sensor

Current

CH1 Dury

Cycle

CH2 Current

CH1 Current

CH2 Duty

Cycle

R2 Shunt

R1 Shunt

REC3

PL7

3 4 5

8

6 7

10

9

37

36

10

5

10

4

10

3

10

2

RED/BLK

RED/BLK

RED/BLK

62 RED

WHT

126 BLU

125 BLK

124 RED

30

29

61

60

V2

RED

PL30

CR1

5

REC30

1

2

6

63

RED/BLK

S1

TEST RED

RUN

W

H

T

B

LU

Y

E

L/

B

LK

R

E

D

/B

LK

11

9

11

8

R

E

D

14

Transformer

High Voltage

3

4

RED

RED

16

15

Supply

120 VAC

R

E

D

W

H

T

13

Supply

120 VAC

Auto

OFF

127

6

5

P

L6

128

R

E

C

2

2

1

Relay

Pilot Arc

74

75

9

8

14

13

12

Reduction

50% Current

Delay Relay

13

7

PL8

11

Y

E

L

W

H

T

B

LU

10

9

3

4

B

LU

W

H

T

13

8

5

12

7

6

REC4

8

2

1

Machine Motion

Machine Motion

Delay Pot

Hold

PCB7

Machine Motion

Valve

PL9

5

4

3

7

6

9

8

10

REC5

PL9

2

1

4

3

6

5

7

Plasma Gas

Valve

Thumbwheel

O

R

N

14

0

13

1

87

86

84

85

13

5

13

6

13

2

2

R

9

Potentiometer

Machine Delay

Opitional

R

E

D

REC20

PL20

1

13

9

WHT

VIO

G

R

N

Y

E

L

B

LU

V

IO

B

R

N

G

R

Y

W

H

T

B

LK

14

2

14

1

14

4

14

3

14

7

14

6

14

5

14

8

GRN

142

ORN

RED

141

139

140

YEL

145

144

143 BLU

200 Amp

M2-4

Switch

M1-2

M1-1

M2-8

Optional

M2-2

M2-1

M2-COM

M1-COM

2-B1

D

6-D4

N

2-B2

C

3-D2

G

3-A2

M

3-D2

H

6-D2

P

5-D3

R

Arc on

IHS Start

IHS Complete

COM

10A

20A

200A

100A

80A

40A

THC Option

Thumbwheel Option

PL9

1 2

4

3

5 6 7

RCC Option 023462

145

BLU

VIO

RED

ORN

140

139

142

141

143

YEL

GRN

144

WHT

7

6

5

4

3

2

1

P

L1

6

1X

4

8

35

4

36

15

9

6

1X

4

15

X

1

10

16

9

15

8

7

3

15

X

1

073045

M1 COM

M2 COM

M2-1

M2-2

M2-4

M2-8

M1-1

M1-2

WHT

VIO

BLU

GRN

YEL

ORN

RED

SHIELD

BLK

WHT

BLK

GRN

BLK

RED

156 BLK

162 BLK

161 RED

164 BLK

163 GRN

165 BLK

166 WHT

023675

013179

013-2-179

013179B4

ELEC/GAS SCHEM: MAX200

N/A

MAX200

4 OF 9

BC

5-9-96

NECESSARY WITH CHAMFER OR RADIUS .015.

MATERIAL

THIS DRAWING AND ALL INFORMATION

FROM HYPERTHERM, INC.

FOR MANUFACTURING OR FABRICATION

CONTAINED THEREON IS CONSIDERED

PROPRIETARY AND MAY NOT BE USED

PURPOSES WITHOUT PERMISSION

ANGULAR

±.5∞

SHARP EDGES. BREAK SHARP EDGES IF

PART MUST BE FREE OF BURRS AND

2 PL DECIMAL

±.01

FRACTIONS

±1/64

3 PL DECIMAL

±.005

DIMENSIONS ARE IN INCHES.

UNLESS OTHERWISE SPECIFIED:

TOLERANCES ARE:

CHECKED BY

APP. BY

DATE

DATE

DRAWN BY

DATE

Box-5010 Hanover, NH 03755-5010 603/643-3441

SCALE

MODEL

SHEET

DRAWING NO.

DESCRIPTION

FILE NAME

A

1

A

B

C

D

4

3

2

1

D

C

B

2

3

4

ITEM NO.

SHEET

SHEET

SHEET

SHEET

SHEET

SHEET

SHEET

SHEET

V