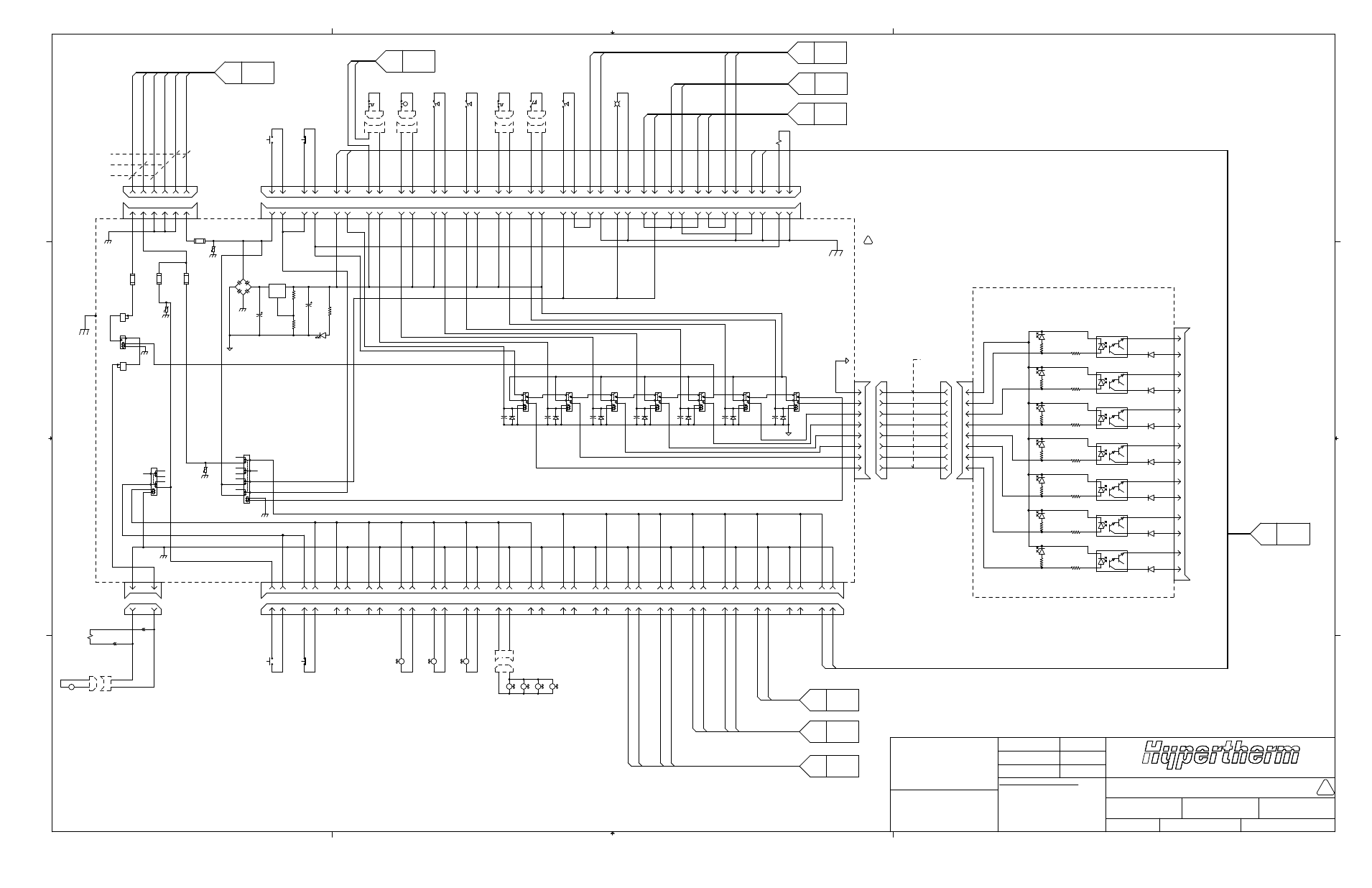

Elec/gas schem: max200 – Инструкция по эксплуатации Hypertherm MAX200 Hand Torch Plasma Arc Cutting System

Страница 159

F1

H1

9

2

M1

106

P

L2

1

2

1

B

LK

V7

PL19

106

REC5

W

H

T

107

107

1

23

23

11

R

E

D

R

E

D

/B

LK

R

E

D

R

E

D

/B

LK

PB1

4

3

PB2

1

2

4

PL2

3

4

REC2

3

7

8

7

8

R

E

D

/B

LK

R

E

D

/B

LK

R

E

D

M2

C

H

1

T

2

12

15 16

26

25

20

19

HX1

R

E

D

/B

LK

R

E

D

/B

LK

R

E

D

R

E

D

M4

M3

C

H

2

M5

M6

1

2

REC31

PL31

24

27

28

24

27 28

6

R

E

D

5

32

31

35

R

E

D

/B

LK

M8

M7

R

E

D

36

1

2

2A

1A

6

5

10

2-B4

A

6

5

1

3

2

4

REC1

O

R

N

240 VAC

115 VAC

PL1

24 VAC

20

Y

E

L

Y

E

L

R

E

D

O

R

N

R

E

D

16

21

18

17

19

PS2

19

15

16

11 12

7

8

4

2

1

3

R

E

D

34

Machine

Remote

STOP

3

98

99

W

H

T

R

E

D

4

10

9

2

R

E

D

W

H

T

PB1

PB2

1

35

13

16

W

H

T

R

E

D

W

H

T

51

50

53

W

H

T

R

E

D

R

E

D

1

2

REC22

PL22

TS1

REC23

PL23

1

2

N

O

LS1

C

O

M

31

32

23

24

29

30

33

34

36 35

27 28

20

11

6

REC25

PL25

W

H

T

FS1

54

52

55

R

E

D

W

H

T

W

H

T

58

59

11

5

R

E

D

T

W

H

R

E

D

N

O

C

O

M

PS1

REC24

PL24

2

1

1

TS2

R

E

D

12

3

17

9

17

8

R

E

D

W

H

T

12

1

12

2

12

0

R

E

D

W

H

T

W

H

T

2

N

O

C

O

M

PS3

X

1

X

2

LT1

5-C4

L

4-B4

M

2-B2

B

R

E

D

/B

LK

R

E

D

/B

LK

R

E

D

/B

LK

R

E

D

R

E

D

R

E

D

30

2B

1B

14 13

29

13

2

13

1

17

18

22 21

R

E

D

/B

LK

R

E

D

/B

LK

R

E

D

R

E

D

30

13

3

13

4

26 25

88

89

29

34 33

REC4

8

7

5

6

4

3

2

1

4-B3

H

6-C4

J

5

6

9

10

14 13

18

21 22

17

26 25

REC3

81

80

11

9

11

8

W

H

T

R

E

D

R

E

D

W

H

T

82

83

72

73

R

E

D

W

H

T

R

E

D

W

H

T

76

77

11

12

R

E

D

W

H

T

R

E

D

W

H

T

PL3

V4

4-D3

G

PL1.4

8

7

023354

1

6

5

4

3

2

REC1

REC2

D4

RN1A

11

6

LED2

8

7

5

RN1H

LED1

RN1G

RN1F

RN1E

U1D

10

9

12

4

3

1

RN1C

RN1D

LED3

RN1B

U1C

14

U1B

13

16

4

D1

1

2

D2

3

D3

5

6

7

2

2

1

LED4

RN2B

LED5

RN2A

RN2F

16

U1A

15

U2A

15

6

5

8

7

RN2H

LED6

RN2E

RN2G

LED7

U2C

12

11

U2D

10

9

11

9

10

8

D7

12

14

D6

D5

13

6-C2

K

ASSY: 041536

PCB: 041535

2-D2

U

15

R

E

D

SHEET

SHEET

SHEET

SHEET

SHEET

SHEET

SHEET

SHEET

SHEET

013179

013-2-179

013179B3

ELEC/GAS SCHEM: MAX200

N/A

MAX200

3 OF 9

BC

5-9-96

NECESSARY WITH CHAMFER OR RADIUS .015.

MATERIAL

THIS DRAWING AND ALL INFORMATION

FROM HYPERTHERM, INC.

FOR MANUFACTURING OR FABRICATION

CONTAINED THEREON IS CONSIDERED

PROPRIETARY AND MAY NOT BE USED

PURPOSES WITHOUT PERMISSION

ANGULAR

±.5∞

SHARP EDGES. BREAK SHARP EDGES IF

PART MUST BE FREE OF BURRS AND

2 PL DECIMAL

±.01

FRACTIONS

±1/64

3 PL DECIMAL

±.005

DIMENSIONS ARE IN INCHES.

UNLESS OTHERWISE SPECIFIED:

TOLERANCES ARE:

CHECKED BY

APP. BY

DATE

DATE

DRAWN BY

DATE

Box-5010 Hanover, NH 03755-5010 603/643-3441

SCALE

MODEL

SHEET

DRAWING NO.

DESCRIPTION

FILE NAME

A

1

A

B

C

D

4

3

2

1

D

C

B

2

3

4

ITEM NO.

V

13

14

CR2

4

13

12

8

14

9

5

1

MOV2

11

12

7

4

8

10

6

2

3

CR1

9

1

5

J1

3

2

CR3

1

J2

C9

MOV3

C8

R3

D9

R1

H2

H3

F2

F3

MOV1

IN

1

3

+

2

-

4

3

1

G

N

D

U1

R2

2

OUT

D8

H4

F4

CR7

5

5

+

8

1

+

8

1

CR4

3

4

6

CR5

3

4

6

5

5

+

8

1

+

8

1

CR6

3

4

6

3

4

6

CR9

5

+

8

1

+

1

8

4

CR8

3

6

3

6

5

5

8

1

+

CR10

4

3

6

4

U

POWER DISTRIBUTION

PCB ASSY: 041534